Durable cotton twill, often indigo-dyed, constructed into garments designed for demanding physical labor characterizes this apparel category. Typical features include reinforced stitching, triple-needle seams, and rivet reinforcements at stress points. Examples include overalls, jackets, and jeans with specific pockets for tools.

The robust construction and functional design of this type of clothing provide exceptional protection and utility for tradespeople, laborers, and other individuals engaged in physically demanding work. Historically, its durability and comfort contributed to its widespread adoption in various industries, ultimately becoming a staple in both workwear and casual attire. This legacy of practicality continues to inform contemporary designs, ensuring its enduring relevance in a range of professional and recreational contexts.

The following sections will delve deeper into specific aspects of this category, exploring variations in design, fabric, and functionality, as well as the evolution of its role in modern wardrobes.

1. Durability

Durability stands as a cornerstone of workwear, particularly for garments like those constructed from denim intended for demanding occupations. The ability to withstand rigorous use, frequent washing, and exposure to harsh conditions dictates the garment’s lifespan and overall value. This section explores key facets contributing to the durability of work denim.

-

Fabric Construction

The tight weave and robust nature of denim contribute significantly to its inherent durability. Specifically, heavier weight denims (measured in ounces per square yard) typically exhibit greater resistance to abrasion and tearing compared to lighter weights. The use of high-quality cotton fibers further enhances the fabric’s strength and resilience.

-

Reinforced Stitching

Triple-needle stitching, a common feature in work denim, uses three parallel rows of stitching for critical seams. This technique significantly increases seam strength, preventing ripping and tearing under stress. Bartack stitching, another reinforcement method, creates dense, secure stitches at stress points like pocket corners and belt loops, adding further resilience.

-

Hardware and Rivets

Metal rivets reinforce high-stress areas like pocket corners and seams, preventing them from pulling apart. The use of heavy-duty zippers and buttons contributes to the overall durability of the garment, ensuring secure closures and prolonged functionality.

-

Dyeing and Finishing

The dyeing process, often using indigo dye, not only imparts the characteristic color but also contributes to the fabric’s durability. Certain finishing processes, like sanforization, minimize shrinkage and maintain the garment’s shape over time, further extending its usable life.

These combined factors ensure that work denim remains a dependable choice for individuals requiring durable, long-lasting apparel capable of withstanding the rigors of demanding professions. Investing in well-constructed work denim ultimately translates to long-term cost savings and reliable protection in the workplace.

2. Comfort

Comfort plays a vital role in workwear, especially for garments worn for extended periods in demanding conditions. Discomfort can hinder productivity and create safety hazards. For individuals relying on work denim, comfort translates directly into enhanced performance and well-being on the job. The following facets illuminate the critical components of comfort in work denim.

-

Fabric Weight and Breathability

While heavier denim offers superior durability, it can compromise breathability. Strategic selection of fabric weight involves balancing durability needs with comfort requirements in specific work environments. Lighter weight denims offer better breathability in warmer climates, promoting air circulation and reducing overheating. Some manufacturers incorporate innovative weaving techniques or blended fabrics to enhance breathability without sacrificing durability.

-

Fit and Cut

The fit and cut of work denim directly impact comfort and range of motion. A relaxed fit allows for greater freedom of movement, crucial for tasks requiring bending, lifting, or crouching. Features like a gusseted crotch provide additional flexibility and prevent tearing. Conversely, a more fitted cut might be preferred for jobs requiring less strenuous movement. Understanding individual job demands helps determine the optimal fit.

-

Construction and Seams

Proper seam construction minimizes chafing and irritation. Flat-felled seams, commonly found in work denim, create a smooth, flat surface against the skin, reducing friction and enhancing comfort during extended wear. Reinforced stitching, while enhancing durability, should also be designed to avoid creating rough or irritating contact points.

-

Moisture Management

In physically demanding jobs, moisture management becomes crucial for comfort. Some work denim incorporates moisture-wicking properties to draw sweat away from the skin, promoting evaporation and keeping the wearer dry and comfortable. This feature becomes especially important in hot and humid work environments.

The interplay of these factors determines the overall comfort level of work denim. Selecting work denim that prioritizes these elements contributes to a safer, more productive, and more comfortable work experience. Ultimately, investing in comfortable workwear demonstrates a commitment to worker well-being and recognizes the direct link between comfort and optimal performance.

3. Reinforced Stitching

Reinforced stitching constitutes a critical component of durable workwear, particularly within the context of men’s work denim. The demanding nature of physical labor necessitates garments capable of withstanding significant stress and strain. Reinforced stitching addresses this requirement by providing enhanced seam integrity and resistance to tearing. This technique involves multiple rows of stitching, often utilizing thicker thread, to create more robust seams compared to standard single-row stitching. Specific types of reinforced stitching commonly found in work denim include triple-needle stitching, characterized by three parallel rows of stitching, and bartack stitching, a dense, localized reinforcement often applied to stress points like pocket corners and belt loops. These methods significantly enhance the garment’s resistance to tearing at vulnerable points, prolonging its lifespan.

The practical significance of reinforced stitching becomes evident in real-world applications. Consider a construction worker repeatedly crouching and bending while carrying heavy tools. The seams of their work pants experience significant stress during these movements. Reinforced stitching ensures the seams withstand this repeated stress, preventing rips and tears that could compromise the garment’s functionality and expose the wearer to potential hazards. Similarly, a mechanic reaching into tight spaces might snag their jacket on a sharp edge. Reinforced stitching minimizes the risk of tearing, preserving the garment’s integrity and protecting the wearer. Such examples illustrate the direct correlation between reinforced stitching and the enhanced durability of work denim.

The incorporation of reinforced stitching underscores a commitment to quality and durability in workwear design. This technique directly addresses the specific demands placed upon garments in physically demanding occupations. While seemingly a minor detail, reinforced stitching plays a pivotal role in ensuring the longevity and functionality of men’s work denim, contributing significantly to its value and protective qualities in challenging work environments. Its presence often signifies a higher quality garment designed to withstand the rigors of professional use.

4. Functional Design

Functional design in men’s work denim prioritizes utility and practicality, catering to the specific needs of demanding professions. Garments are engineered to enhance efficiency and safety in the workplace, incorporating features that go beyond basic apparel. This inherent practicality distinguishes work denim from casual denim, reflecting a focus on performance and durability in challenging environments.

-

Specialized Pockets

Work denim often features specialized pockets designed for specific tools and equipment. Hammer loops, reinforced pockets for utility knives, and ruler pockets exemplify this focus on practicality. These purpose-built features streamline workflow by providing readily accessible storage for essential items, eliminating the need for separate tool belts and enhancing overall efficiency.

-

Reinforced Stress Points

Areas prone to wear and tear, such as knees and elbows, often receive reinforcement through double layering of fabric or the addition of specialized panels. This strategic reinforcement enhances the garment’s lifespan, ensuring sustained protection and functionality in high-stress areas. These reinforcements directly address the demands of physical labor, mitigating the risk of tears and abrasions in vulnerable locations.

-

Durable Hardware

Heavy-duty zippers, rivets, and buttons contribute to the overall functionality and longevity of work denim. These robust components withstand the rigors of daily use, ensuring secure closures and reliable performance. Metal rivets at stress points, for instance, prevent seams from pulling apart, maintaining the garment’s structural integrity under pressure.

-

Adaptable Designs

Functional design also considers adaptability to various work environments. Detachable hoods, adjustable cuffs, and integrated tool loops exemplify this versatility. These features allow wearers to customize the garment to suit specific tasks or weather conditions, optimizing comfort and practicality across a range of work scenarios.

These functional design elements underscore the distinction between work denim and casual denim. While aesthetics play a role, the emphasis on utility and durability remains paramount in work denim. The strategic incorporation of specialized features enhances worker safety, efficiency, and comfort, solidifying work denim’s essential role in supporting demanding professions.

5. Rivet Reinforcements

Rivet reinforcements constitute a crucial element in the construction of durable and long-lasting men’s work denim. These metal fasteners, typically made of copper or brass, are strategically placed at high-stress points like pocket corners, belt loops, and seam intersections. Their primary function is to distribute stress and prevent tearing or ripping of the fabric under demanding work conditions. This reinforcement extends the lifespan of the garment, ensuring its continued functionality and providing value to the wearer.

The historical context of rivet reinforcements in work denim traces back to the late 19th century. Levi Strauss & Co., recognizing the need for more robust workwear, patented the use of rivets in denim pants in 1873. This innovation addressed a common problem: seams tearing under the strain of heavy labor. Miners, farmers, and other laborers benefited significantly from this reinforced design, which provided unparalleled durability in demanding occupations. This historical precedent underscores the enduring practicality of rivet reinforcements in work denim.

The practical significance of rivet reinforcements becomes apparent in contemporary work environments. Consider a construction worker carrying heavy tools in their pockets. The weight and movement of these tools place significant stress on the pocket seams. Rivet reinforcements distribute this stress, preventing the seams from tearing and ensuring the pockets remain functional. Similarly, a mechanic frequently kneeling or crouching places stress on the seams in the knee area. Reinforced seams with rivets maintain the integrity of the garment, preventing premature wear and tear. These examples highlight the critical role rivet reinforcements play in ensuring the durability and longevity of men’s work denim, ultimately contributing to worker safety and productivity.

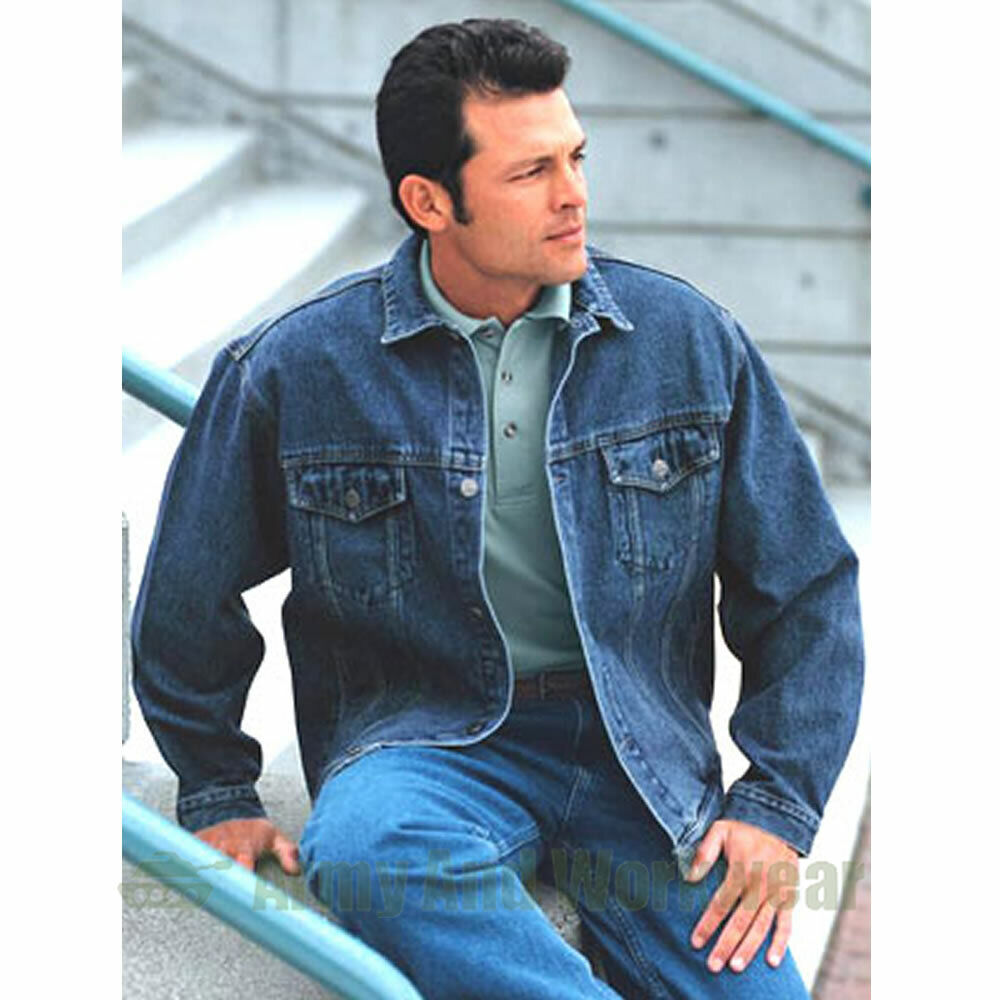

6. Variety of Styles

The availability of a variety of styles in men’s work denim reflects the diverse needs of various professions and work environments. This range extends beyond the classic five-pocket jean, encompassing overalls, coveralls, jackets, vests, and shirts. Each style caters to specific functionalities and levels of protection required in different trades. Overalls, for example, provide full-body coverage and multiple pockets suitable for construction or agricultural work. Jackets offer additional warmth and protection in colder climates or for tasks involving welding or handling hazardous materials. The variety allows individuals to select the most appropriate garment for their specific job requirements, optimizing both safety and performance.

This diversity in style also contributes to the versatility of work denim. A carpenter might opt for jeans with reinforced knees and tool pockets, while a welder requires a flame-resistant denim jacket for protection against sparks and heat. The availability of specialized designs ensures workers can find appropriate attire that addresses the specific hazards and demands of their respective professions. This tailored approach to workwear enhances both safety and efficiency in the workplace. Furthermore, the variety of styles enables work denim to adapt to different climates and weather conditions. Lined jackets offer warmth in colder temperatures, while lighter-weight denim shirts provide breathability in warmer climates. This adaptability ensures year-round comfort and practicality, regardless of the external environment.

The broad spectrum of styles available in men’s work denim underscores its adaptability and continued relevance across numerous industries. This variety ensures that individuals in diverse professions can find appropriate and functional attire tailored to their specific needs. Understanding the relationship between style and functionality in work denim contributes to informed purchasing decisions, promoting both safety and productivity in the workplace. Ultimately, the variety of styles strengthens work denim’s position as a versatile and essential component of professional attire across a wide range of demanding occupations.

Frequently Asked Questions

This section addresses common inquiries regarding work denim, providing concise and informative responses to clarify key aspects of this essential workwear category.

Question 1: How does one determine the appropriate weight of denim for specific work tasks?

Denim weight, measured in ounces per square yard (oz/sq yd), directly correlates with durability and warmth. Heavier weights (12 oz/sq yd and above) offer increased protection and insulation, suitable for demanding outdoor work or colder climates. Lighter weights (10 oz/sq yd and below) provide greater breathability and flexibility, ideal for warmer conditions or indoor tasks requiring greater range of motion. Consider the specific demands of the job, including the level of physical activity, potential hazards, and environmental conditions, to determine the appropriate weight.

Question 2: What distinguishes work denim from standard denim jeans?

Work denim prioritizes durability and functionality over fashion. Reinforced stitching, rivet reinforcements at stress points, specialized pockets for tools, and often heavier-weight denim construction differentiate work denim from standard jeans. These features enhance the garment’s resistance to wear and tear, prolonging its lifespan in demanding work environments. While standard jeans may offer some level of durability, they typically lack the specialized features and robust construction necessary for sustained performance in demanding physical labor.

Question 3: How should work denim be cared for to maximize its lifespan?

Proper care significantly extends the life of work denim. Washing inside out in cold water with a mild detergent helps preserve the color and prevent excessive wear. Avoid using bleach or harsh chemicals. Line drying is generally recommended to minimize shrinkage and maintain the integrity of the fabric. Ironing, if necessary, should be done at low temperatures. Following these care instructions ensures the garment remains functional and comfortable for an extended period.

Question 4: What are the key considerations when selecting work denim for specific trades?

Specific trades require specialized features in work denim. Welders, for instance, require flame-resistant denim for protection against sparks and heat. Carpenters might prioritize reinforced knee panels and tool pockets, while electricians may benefit from insulated denim for protection against electrical hazards. Consider the inherent risks and demands of the trade when selecting appropriate work denim to ensure adequate protection and functionality.

Question 5: What role do rivets play in the durability of work denim?

Rivets reinforce high-stress areas like pocket corners and seam intersections. These metal fasteners distribute stress, preventing tearing and ripping under pressure. Their strategic placement enhances the overall durability of the garment, particularly in areas subjected to frequent strain during physical labor. This reinforcement extends the usable life of the garment, contributing to its long-term value.

Question 6: How can one ensure proper fit and comfort when purchasing work denim?

Consider the intended use and personal preference when selecting the fit of work denim. A relaxed fit provides greater freedom of movement, suitable for tasks requiring frequent bending and crouching. A more fitted style may be preferable for jobs involving less strenuous activity. Consulting size charts and trying on different styles can help determine the optimal fit for individual body types and work requirements. Proper fit enhances both comfort and mobility on the job.

Understanding these key aspects of work denim empowers informed purchasing decisions, ensuring the selected garment aligns with the specific demands of the profession and contributes to both safety and productivity in the workplace.

The following section will delve into specific product recommendations and brand comparisons to further assist in selecting the ideal work denim for individual needs.

Essential Tips for Selecting and Maintaining Work Denim

This section offers practical guidance for maximizing the value and lifespan of work denim investments. Careful consideration of these tips ensures optimal performance, safety, and comfort in demanding work environments.

Tip 1: Prioritize Fit and Function Over Fashion

While aesthetics play a role, the primary focus should be on functionality and durability. A proper fit allows for a full range of motion without restriction, while features like reinforced seams and specialized pockets contribute to long-term performance and safety.

Tip 2: Consider Fabric Weight and Breathability

Heavier denim offers greater durability, while lighter denim provides enhanced breathability. Select the appropriate weight based on the work environment and level of physical activity. Breathability becomes crucial in hot or humid conditions, preventing overheating and discomfort.

Tip 3: Inspect Reinforcement Points and Stitching

Examine areas like pocket corners, belt loops, and seams for reinforced stitching and rivets. These reinforcements indicate a higher level of durability and resistance to wear and tear, essential for demanding work environments.

Tip 4: Choose Appropriate Hardware

Heavy-duty zippers, buttons, and rivets contribute to the overall longevity of the garment. Ensure these components are robust and securely fastened to withstand frequent use and stress.

Tip 5: Select Denim with Functional Design Features

Specialized pockets, reinforced knees, and hammer loops enhance practicality and efficiency on the job. Consider the specific needs of the profession and choose denim with features that streamline workflow and improve safety.

Tip 6: Understand Care Instructions

Proper care maximizes the lifespan of work denim. Follow manufacturer instructions regarding washing, drying, and ironing to maintain the garment’s integrity and prevent premature wear.

Tip 7: Invest in Quality Over Quantity

High-quality work denim, while potentially more expensive initially, offers greater long-term value due to its increased durability and longevity. Consider the investment as a contribution to both safety and productivity.

Adherence to these guidelines ensures the selection of durable, comfortable, and functional work denim capable of withstanding the rigors of demanding professions. Investing in appropriate workwear contributes to both worker safety and long-term cost savings.

The concluding section will summarize the key benefits of investing in quality work denim and reinforce its crucial role in supporting various industries.

Conclusion

This exploration of durable, purpose-built apparel highlights the critical intersection of functionality, durability, and comfort. Reinforced stitching, rivet reinforcements, and specialized design elements contribute to garments engineered for demanding work environments. The variety of available styles reflects the diverse needs of various trades, underscoring the adaptability and enduring relevance of this essential workwear category.

Prioritizing quality and fit ensures not only worker safety and enhanced productivity but also represents a long-term investment in professional attire. Careful selection and proper maintenance maximize the lifespan of these garments, contributing to sustainable practices and recognizing the value of well-crafted, purpose-driven workwear.