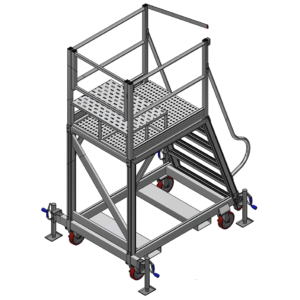

These supports are fundamental to any workbench, providing stability and load-bearing capacity. A typical example consists of four vertical members, often constructed from metal or wood, positioned at each corner of the work surface. Variations exist, including designs with central supports for enhanced weight distribution and specialized configurations for specific tasks or environments.

Robust and well-designed supports are essential for safe and efficient operation. They enable the workbench to withstand the weight of tools, materials, and the forces applied during work. Historically, designs have evolved alongside crafting practices, adapting to accommodate heavier machinery and more demanding tasks. A stable platform is paramount for precision work, preventing wobble and ensuring accurate results. Furthermore, appropriately designed supports contribute to ergonomic comfort by allowing users to work at a suitable height and posture.

The following sections delve into material selection, construction techniques, and design considerations for creating or selecting suitable supports for diverse applications, ranging from light-duty hobby work to heavy-duty industrial use.

1. Stability

Stability is paramount for a functional workbench. The base directly influences the workbench’s ability to remain stationary and level under load and during operation. Inadequate stability can lead to dangerous work conditions, compromised precision, and damage to equipment or materials. A workbench prone to wobbling or tipping poses significant safety risks, particularly when working with heavy objects or power tools. For instance, a shaky workbench can cause a workpiece to shift unexpectedly during sawing or drilling, leading to injury. Similarly, insufficient support can cause the entire workbench to collapse under excessive weight.

Several factors contribute to workbench stability. These include the design and construction of the supports, the material used, the overall workbench weight, and the distribution of load. Widely spaced supports provide a larger base of support, enhancing stability. Materials like steel offer greater rigidity compared to lighter materials like aluminum or wood. A heavier workbench is inherently more stable due to its increased inertia. Evenly distributing weight across the work surface minimizes the risk of tipping. Consider a workbench with a heavy vise mounted at one end. Without adequate reinforcement or counterbalancing weight, such an arrangement can compromise stability.

Ensuring stability requires careful consideration of these factors. Proper design and construction techniques, including bracing and reinforcement, play a crucial role. Choosing appropriate materials based on anticipated loads is essential. Practicing mindful weight distribution and avoiding overloading the workbench further contribute to a safe and stable working environment. Addressing stability issues proactively through robust design and mindful usage is critical for maximizing workbench functionality and ensuring user safety.

2. Material

The material composition of supports directly influences the workbench’s durability, weight capacity, and overall performance. Selecting the appropriate material is crucial, as it dictates the workbench’s suitability for specific tasks and environments. Choosing between wood, metal, or composite materials requires careful consideration of factors such as intended use, budget, and desired aesthetic.

-

Wood

Wood offers a classic aesthetic and is often chosen for its workability and affordability. Hardwoods like maple and oak provide excellent strength and durability for general-purpose workbenches. Softwoods like pine are more budget-friendly but may require additional reinforcement for heavy-duty applications. Wooden supports can be susceptible to moisture damage and rot, requiring appropriate sealing and maintenance.

-

Metal

Metal, typically steel or aluminum, provides superior strength and resistance to moisture and pests. Steel supports offer exceptional load-bearing capacity, making them ideal for heavy-duty industrial workbenches. Aluminum offers a lighter-weight alternative, suitable for mobile or lighter-duty applications. Metal supports are typically more expensive than wood but offer increased longevity and resilience.

-

Composite Materials

Composite materials, such as engineered wood or plastic-wood blends, offer a balance of affordability, durability, and moisture resistance. These materials often incorporate recycled content, making them a sustainable choice. While generally less strong than solid wood or metal, composite supports can provide adequate performance for light to medium-duty applications. Their resistance to moisture and pests makes them a practical choice for environments where these factors are a concern.

-

Considerations for Material Selection

Material selection requires careful consideration of the intended use, environment, and budget. Heavy-duty applications demand robust materials like steel, while lighter tasks may suffice with wood or composites. Environmental factors, such as humidity and temperature fluctuations, influence material susceptibility to degradation. Finally, budget constraints often play a significant role in material selection, requiring a balance between cost and performance.

The chosen material significantly impacts the workbench’s long-term performance and suitability for specific tasks. Understanding the properties of each material and their respective advantages and disadvantages is crucial for informed decision-making. A careful assessment of the intended use and environment will guide the selection process, ensuring a workbench tailored to specific needs and requirements.

3. Height

Proper workbench height is crucial for user comfort, efficiency, and safety. An ill-suited height can lead to musculoskeletal strain, reduced productivity, and increased risk of accidents. This section explores the critical aspects of workbench height and its implications for various tasks and individuals.

-

Ergonomics and Posture

Ergonomics plays a vital role in determining the appropriate workbench height. A workbench that is too high or too low forces users into awkward postures, leading to back pain, neck strain, and other musculoskeletal issues. Prolonged work in uncomfortable positions can result in chronic health problems. Proper height allows for a neutral posture, minimizing strain and maximizing comfort during extended work periods.

-

Task Specificity

Different tasks require different workbench heights. Delicate, precision work often benefits from a higher work surface, allowing for closer visual inspection and finer control. Conversely, tasks involving heavy lifting or forceful movements may require a lower workbench height to leverage body weight and reduce strain. Consider the primary tasks performed on the workbench to determine the optimal height for efficient and safe operation.

-

Individual User Needs

User height significantly influences the ideal workbench height. A one-size-fits-all approach is inadequate, as individuals of varying heights require different work surface levels for comfortable and efficient operation. Adjustable-height workbenches offer a versatile solution, accommodating users of different statures and allowing for height adjustments based on specific tasks. In shared workspaces, adjustable height is essential to accommodate diverse users.

-

Impact on Productivity and Safety

Proper workbench height directly impacts productivity and safety. A comfortable working height reduces fatigue and allows for sustained focus, leading to increased productivity. Conversely, an uncomfortable height can lead to distractions, errors, and an increased risk of accidents. Furthermore, proper height facilitates the correct application of force and control, minimizing the risk of injuries related to awkward postures or excessive strain.

Careful consideration of these factors is essential when determining workbench height. Prioritizing ergonomics, task requirements, and individual user needs ensures a comfortable, efficient, and safe working environment. Investing in adjustable-height mechanisms offers long-term flexibility and adaptability to changing tasks and user preferences. A properly configured workbench enhances both productivity and well-being, contributing to a positive and efficient work experience.

4. Design

Support design significantly influences workbench functionality, stability, and adaptability. Several design elements warrant careful consideration, including material choice, construction techniques, bracing, and integration of additional features. These elements interact to determine the workbench’s overall performance and suitability for specific tasks.

Material selection dictates the supports’ strength, durability, and resistance to environmental factors. Steel offers superior load-bearing capacity for heavy-duty applications, while wood provides a more traditional aesthetic and workability for lighter tasks. Construction techniques, such as welding for metal supports or joinery for wood, directly impact the structural integrity and longevity of the workbench. Proper bracing reinforces the supports, enhancing stability and preventing racking under load. Consider a workbench intended for heavy metalworking. Supports constructed from robust steel profiles, reinforced with cross-bracing and gussets, provide the necessary rigidity to withstand the forces generated during operations like hammering or grinding. Conversely, a workbench for delicate electronics repair might prioritize a lighter, more open design, utilizing aluminum supports and minimal bracing to maximize access and visibility.

Integration of additional features further expands workbench functionality. Adjustable-height mechanisms accommodate users of different statures and varying task requirements. Casters enhance mobility, allowing for easy relocation within the workspace. Integrated storage solutions, such as drawers or shelves, optimize organization and keep tools readily accessible. Understanding the interplay of these design elements is crucial for selecting or constructing a workbench tailored to specific needs. Careful consideration of material properties, construction techniques, bracing strategies, and integrated features ensures a functional, stable, and adaptable workspace. A well-designed workbench enhances productivity, promotes user comfort, and contributes to a safe and efficient working environment.

5. Adjustability

Adjustability in workbench supports offers significant advantages, enhancing ergonomics, accommodating diverse tasks, and ensuring long-term utility. The ability to modify the work surface height is crucial for maintaining proper posture, accommodating various users, and adapting to evolving project requirements. This adaptability contributes directly to user comfort, efficiency, and the workbench’s overall lifespan.

-

Accommodating Varying User Heights

Individuals differ in height, and a fixed-height workbench inevitably leads to discomfort and potential strain for some users. Adjustable supports allow each individual to customize the work surface height to their specific needs, promoting proper posture and reducing the risk of musculoskeletal issues. This is particularly important in shared workspaces or environments where multiple users access the same workbench. For example, a taller individual might raise the workbench for comfortable woodworking, while a shorter individual might lower it for detailed electronics assembly.

-

Adapting to Different Tasks

Different tasks often benefit from varying work surface heights. Intricate, detail-oriented work may require a higher surface for better visibility and closer proximity, while tasks involving heavy objects or forceful movements might necessitate a lower height for better leverage and stability. Adjustable supports allow users to optimize the work surface height for each specific task, enhancing both efficiency and safety. Consider a workbench used for both jewelry making and furniture repair. The adjustable supports allow the user to raise the surface for fine detail work on jewelry and lower it for the more physically demanding tasks associated with furniture repair.

-

Compensating for Uneven Floors

Many workspaces, particularly in older buildings or garages, have uneven floors. A fixed-height workbench on an uneven floor can wobble, creating instability and safety hazards. Adjustable supports allow users to level the work surface, ensuring stability regardless of floor irregularities. This is crucial for maintaining accuracy and preventing accidents, particularly when working with delicate equipment or hazardous materials.

-

Enhancing Ergonomics and Long-Term Health

Ergonomics is paramount for long-term health and well-being. Adjustable supports play a vital role in promoting proper posture and reducing strain during prolonged work periods. By allowing users to customize the work surface height, adjustable supports minimize the risk of back pain, neck strain, and other musculoskeletal issues. This contributes to a more comfortable and productive work environment, reducing lost time due to injury and promoting long-term health and well-being.

The adjustability offered by adaptable supports is a significant advantage in modern workbenches. By accommodating diverse user needs, varying task requirements, and challenging environments, adjustable supports contribute to a more versatile, comfortable, and productive workspace. This adaptability ensures the workbench remains a valuable asset over time, adapting to evolving needs and promoting long-term user satisfaction.

Frequently Asked Questions

This section addresses common inquiries regarding workbench supports, providing concise and informative responses to facilitate informed decision-making.

Question 1: What materials are most commonly used for constructing these supports?

Steel and wood are the most prevalent materials. Steel offers superior strength and durability for heavy-duty applications, while wood provides a more traditional aesthetic and is often preferred for lighter-duty workbenches.

Question 2: How does one determine the appropriate height for a workbench?

The ideal height depends on the user’s height and the intended tasks. Generally, the work surface should be at a height that allows the user to work comfortably with a straight back and relaxed shoulders. Adjustable-height mechanisms offer optimal flexibility.

Question 3: Are adjustable supports worth the additional cost?

Adjustable supports offer significant ergonomic benefits and accommodate diverse users and tasks. While they typically increase the initial cost, the long-term benefits of adaptability and enhanced user comfort often outweigh the additional expense.

Question 4: How can stability be maximized in a workbench design?

Stability depends on factors like support design, material choice, and weight distribution. Wide supports, robust materials like steel, and even weight distribution contribute to a stable work surface. Bracing and reinforcement further enhance stability.

Question 5: What are the advantages of using metal supports over wooden ones?

Metal supports offer greater strength, durability, and resistance to moisture and pests compared to wood. They are ideal for heavy-duty applications and environments where moisture or pests are a concern. However, metal can be more expensive than wood.

Question 6: How can one maintain and prolong the lifespan of workbench supports?

Regular cleaning, inspection for damage, and prompt repairs are essential for maintaining supports. Wood supports benefit from periodic sealing or painting to protect against moisture. Metal supports should be inspected for rust and treated accordingly.

Careful consideration of these frequently asked questions provides a deeper understanding of factors influencing workbench functionality and longevity. Prioritizing stability, ergonomics, and appropriate material selection ensures a safe, efficient, and productive workspace.

The next section delves into specific workbench designs tailored to various applications, from woodworking to electronics repair.

Essential Tips for Workbench Support Selection

Selecting appropriate supports is crucial for workbench functionality and longevity. These tips offer guidance for optimizing stability, ergonomics, and durability.

Tip 1: Prioritize Stability

Stability is paramount for safe and efficient operation. Opt for designs with a wide base and robust materials. Consider bracing for enhanced rigidity, particularly for heavy-duty applications. A stable workbench minimizes risks and ensures accurate work.

Tip 2: Consider Material Properties

Material selection dictates durability and performance. Steel offers superior strength for heavy loads, while wood provides a classic aesthetic and workability. Composites offer a balance of affordability and moisture resistance. Choose a material suited to the intended tasks and environment.

Tip 3: Ergonomics Are Key

Proper height is crucial for user comfort and preventing strain. Consider adjustable-height mechanisms to accommodate diverse users and tasks. An ergonomic setup promotes productivity and long-term well-being.

Tip 4: Evaluate Load Capacity

Assess the anticipated weight of tools, materials, and workpieces. Supports should have ample load capacity to prevent instability or collapse. Overloading a workbench compromises safety and can lead to structural damage.

Tip 5: Think Long-Term

Consider future needs and potential changes in workspace or tasks. Investing in a durable, adaptable workbench with robust supports ensures long-term functionality and avoids premature replacement. Flexibility accommodates evolving requirements.

Tip 6: Factor in the Environment

Environmental conditions influence material selection and maintenance requirements. High-humidity environments necessitate moisture-resistant materials. Outdoor workbenches require weather-resistant finishes. Protecting the supports prolongs their lifespan.

Tip 7: Don’t Overlook Aesthetics

While functionality is paramount, aesthetics also contribute to a positive work environment. Consider the overall design and how the supports complement the workspace. A cohesive aesthetic enhances the workspace and promotes a positive work experience.

Adhering to these guidelines ensures selection of suitable supports for diverse needs and applications. A well-chosen foundation enhances workbench functionality, promotes user comfort, and ensures long-term durability.

The following conclusion summarizes the key takeaways for optimizing workbench design and functionality.

Conclusion

Appropriate structural underpinnings are essential for workbench functionality and longevity. Material selection, height, design, and adjustability are crucial factors influencing stability, ergonomics, and adaptability. Robust designs, crafted from appropriate materials like steel or hardwood, provide a stable platform for diverse tasks. Correct height ensures user comfort and minimizes strain, while adjustable mechanisms accommodate varying user statures and task requirements. Furthermore, thoughtful design considerations, such as bracing and reinforcement, enhance stability and load-bearing capacity.

A well-designed and properly constructed foundation is an investment in long-term productivity and user well-being. Prioritizing these elements contributes to a safe, efficient, and comfortable work environment, maximizing the workbench’s utility and lifespan. Ultimately, informed decision-making regarding these critical structural elements is essential for optimizing workspace functionality and achieving project success.