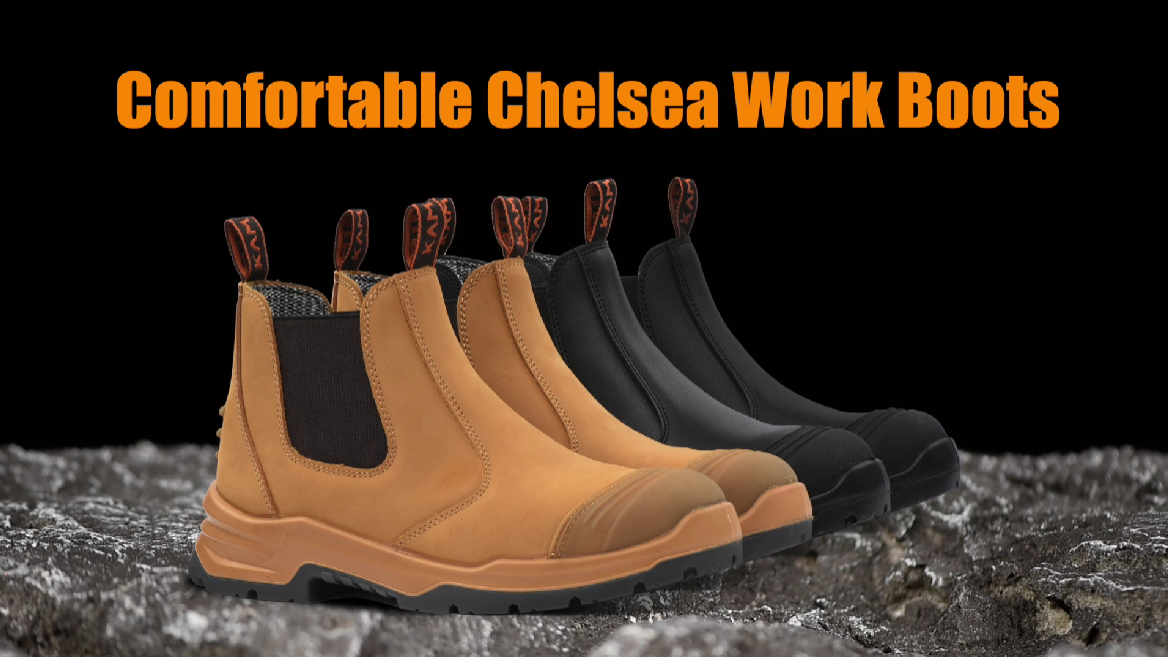

Work boots slip on are a type of footwear designed to provide protection and support in occupational settings. They are typically made of durable materials such as leather or rubber and feature a slip-on design for ease of use. Work boots slip on are often used in industries such as construction, manufacturing, and agriculture, where workers need sturdy and comfortable footwear that can withstand harsh conditions.

The importance of work boots slip on cannot be understated. They provide essential protection for workers’ feet from hazards such as falling objects, sharp edges, and electrical shocks. Additionally, work boots slip on can help to reduce fatigue and discomfort by providing support and cushioning for the feet. Historically, work boots slip on have evolved significantly to meet the changing needs of workers. Early work boots were often heavy and cumbersome, but modern work boots slip on are designed to be lightweight and flexible while still providing the necessary protection.

Today, there is a wide range of work boots slip on available to meet the specific needs of different industries and applications. Some of the most common types of work boots slip on include:

- Steel-toe work boots slip on: These boots feature a steel toe cap to protect the feet from falling objects.

- Composite-toe work boots slip on: These boots feature a composite toe cap that is lighter and more flexible than steel, while still providing excellent protection.

- Electrical hazard work boots slip on: These boots are designed to protect workers from electrical shocks.

- Waterproof work boots slip on: These boots are made of waterproof materials to keep the feet dry in wet conditions.

When choosing work boots slip on, it is important to consider the specific hazards and conditions that workers will be exposed to. It is also important to ensure that the boots fit properly and provide adequate support and comfort.

1. Protection

Work boots slip on play a crucial role in protecting workers’ feet from potential hazards in various occupational settings. Their protective features are essential for ensuring workplace safety and minimizing the risk of injuries.

- Impact Protection: Work boots slip on are designed with reinforced toe caps, often made of steel or composite materials. These toe caps provide protection against falling objects, preventing severe injuries to the toes and feet.

- Puncture Resistance: The soles of work boots slip on are constructed with puncture-resistant materials, safeguarding the feet from sharp objects that could penetrate regular footwear. This feature is particularly important in industries where workers handle sharp tools or work on uneven surfaces.

- Electrical Hazard Protection: For electrical workers, specialized work boots slip on are available with electrical hazard protection. These boots are designed to insulate the feet from electrical currents, reducing the risk of electrical shocks and electrocution.

- Slip Resistance: Work boots slip on often feature slip-resistant outsoles to enhance stability on slippery surfaces. This is crucial in preventing slips and falls, which can lead to serious injuries.

The protective features of work boots slip on are vital for workers in various industries, including construction, manufacturing, and electrical work. By safeguarding feet from potential hazards, these boots contribute to a safer and more productive work environment.

2. Comfort

In the context of work boots slip on, comfort is paramount, as workers often spend long hours on their feet in demanding environments. Work boots slip on are meticulously engineered with support and cushioning to minimize fatigue and discomfort, ensuring optimal performance and well-being.

- Ergonomic Design: Work boots slip on are designed with ergonomic principles, providing ample arch support, heel cushioning, and a snug fit. This reduces strain on the feet, ankles, and legs, promoting comfort even during prolonged wear.

- Cushioning and Support: The midsoles of work boots slip on are often equipped with cushioning materials like EVA or polyurethane, absorbing shock and reducing impact on the feet. Additionally, insoles provide additional support and cushioning, conforming to the unique contours of each foot.

- Moisture Management: To combat sweat and odor, work boots slip on often incorporate moisture-wicking materials that draw perspiration away from the feet. This keeps feet dry and comfortable, preventing blisters and other foot problems.

- Flexibility and Breathability: Work boots slip on are designed to be flexible, allowing for a natural range of motion without compromising support. Breathable materials, such as mesh or leather, enhance airflow, preventing feet from overheating.

The focus on comfort in work boots slip on is not merely a luxury but a necessity. By minimizing fatigue and discomfort, these boots empower workers to perform their duties more efficiently and safely, reducing the risk of workplace accidents and injuries.

3. Slip Resistance

Slip resistance is a crucial feature of work boots slip on, as it plays a pivotal role in preventing slips and falls in hazardous work environments. Slip-resistant outsoles are designed to grip various surfaces securely, ensuring stability and reducing the risk of accidents.

- Traction and Grip: Slip-resistant outsoles are engineered with patterns and materials that enhance traction and grip on slippery surfaces, such as wet floors, icy roads, and oily surfaces. This is achieved through specialized tread designs, rubber compounds, and siping (small slits) that increase the surface area in contact with the ground.

- Coefficient of Friction: The coefficient of friction measures the resistance to slipping between two surfaces. Slip-resistant outsoles are designed to have a high coefficient of friction, ensuring a strong grip on slippery surfaces. This prevents uncontrolled sliding and promotes stability, especially when carrying heavy loads or navigating uneven terrain.

- Workplace Safety: Slip-resistant work boots slip on significantly reduce the risk of slips and falls in workplaces where slippery surfaces are common. This is particularly important in industries such as construction, manufacturing, and healthcare, where spills, wet conditions, and uneven surfaces pose potential hazards.

- Injury Prevention: By preventing slips and falls, slip-resistant work boots slip on help protect workers from injuries such as fractures, sprains, and head trauma. These injuries can not only cause pain and discomfort but also lead to lost workdays, reduced productivity, and increased healthcare costs.

In conclusion, slip resistance is a vital feature of work boots slip on, contributing to workplace safety and injury prevention. Slip-resistant outsoles provide enhanced traction and grip on slippery surfaces, reducing the risk of slips and falls and safeguarding workers from potential harm.

4. Durability

The durability of work boots slip on is paramount in ensuring their ability to withstand the rigors of demanding work environments. Constructed from robust materials like leather and rubber, these boots are designed to endure harsh conditions and provide long-lasting protection for workers’ feet.

-

Material Resilience:

Leather and rubber are renowned for their durability and resistance to wear and tear. Leather is a natural material that is both strong and flexible, providing excellent protection against punctures and abrasions. Rubber, on the other hand, is known for its shock-absorbing properties and resistance to chemicals and oils.

-

Construction and Craftsmanship:

Work boots slip on are meticulously crafted with sturdy construction methods and reinforced stitching. This ensures that the boots can withstand heavy use and maintain their integrity over time. The seams and joints are carefully sealed to prevent moisture and debris from entering, enhancing the boot’s durability.

-

Resistance to Elements:

Work boots slip on are designed to withstand various environmental conditions. The leather and rubber materials provide resistance to water, snow, and extreme temperatures, keeping feet dry and protected in all types of weather.

-

Extended Lifespan:

The combination of durable materials and robust construction contributes to the extended lifespan of work boots slip on. With proper care and maintenance, these boots can last for several years, providing a cost-effective and reliable footwear solution for workers in demanding environments.

The durability of work boots slip on is a critical factor in ensuring worker safety and productivity. By withstanding the rigors of demanding work environments, these boots provide reliable protection and support, allowing workers to perform their jobs with confidence.

5. Convenience

The convenience offered by the slip-on design is a significant advantage of work boots slip on. This design eliminates the need for laces or buckles, enabling workers to don and remove their boots quickly and effortlessly. This is particularly beneficial in situations where time is of the essence or when workers need to frequently take their boots on and off, such as when entering and exiting hazardous areas or when performing tasks that require frequent movement.

The ease of use provided by the slip-on design not only saves time but also reduces fatigue and strain associated with tying and untying laces. This can be especially important for workers who spend long hours on their feet or who need to frequently remove their boots for short periods.

Furthermore, the slip-on design enhances workplace safety by allowing workers to quickly put on their boots in emergency situations, such as when there is a need to evacuate or respond to an incident. The ability to don and remove work boots slip on quickly and easily contributes to overall workplace efficiency, productivity, and safety.

6. Versatility

The versatility of work boots slip on is a key aspect that contributes to their widespread adoption across various industries. The availability of different styles and features allows work boots slip on to be tailored to the specific needs and requirements of different work environments.

For instance, in the construction industry, work boots slip on are often designed with steel toes to protect workers from falling objects and heavy machinery. These boots may also feature slip-resistant outsoles for stability on uneven surfaces and water-resistant materials to keep feet dry in wet conditions.

In the manufacturing industry, work boots slip on may be designed with anti-static properties to prevent electrostatic discharge, which is crucial in environments where flammable materials are handled. These boots may also feature puncture-resistant soles to protect against sharp objects and chemical-resistant materials to withstand exposure to hazardous substances.

The versatility of work boots slip on extends beyond these examples, with specialized designs available for industries such as mining, transportation, and healthcare. By catering to the specific needs of each industry, work boots slip on enhance safety, comfort, and productivity in diverse work environments.

Frequently Asked Questions about Work Boots Slip On

This section addresses frequently asked questions surrounding work boots slip on, providing informative answers to common concerns and misconceptions.

Question 1: What are the key benefits of work boots slip on?

Work boots slip on offer a range of benefits, including protection, comfort, slip resistance, durability, convenience, and versatility. They safeguard feet from hazards, minimize fatigue, enhance stability on slippery surfaces, withstand demanding work environments, allow for quick donning and removal, and cater to specific industry needs.

Question 2: What materials are commonly used in work boots slip on?

Work boots slip on are typically constructed from durable materials such as leather and rubber. Leather provides strength, flexibility, and protection against punctures and abrasions, while rubber offers shock absorption, resistance to chemicals and oils, and slip resistance.

Question 3: Are work boots slip on suitable for all work environments?

The suitability of work boots slip on depends on the specific work environment and its associated hazards. While they offer general protection and comfort, specialized work boots may be necessary in certain industries, such as those requiring electrical hazard protection, puncture resistance, or chemical resistance.

Question 4: How can I ensure a proper fit when choosing work boots slip on?

To ensure a proper fit, it is recommended to wear socks similar to those worn during work when trying on work boots slip on. The boots should fit snugly without causing discomfort or excessive movement. Adequate space should be available in the toe box to prevent cramping.

Question 5: How often should work boots slip on be replaced?

The frequency of replacement depends on the usage and care of the boots. Regular inspection is crucial, and replacement should be considered when the boots show signs of significant wear, damage, or reduced protection.

Question 6: What are some tips for maintaining work boots slip on?

To maintain work boots slip on, it is important to clean them regularly with a damp cloth. Leather boots may require occasional conditioning to preserve their durability. Avoid exposing the boots to extreme heat or chemicals, and allow them to dry thoroughly after use.

Understanding these frequently asked questions can assist individuals in making informed decisions when selecting and using work boots slip on, ensuring optimal foot protection, comfort, and safety in various work environments.

Transition to the next article section: Exploring Advanced Features of Work Boots Slip On

Tips for Selecting and Using Work Boots Slip On

To ensure optimal protection, comfort, and durability of work boots slip on, consider the following tips:

Tip 1: Assess Workplace Hazards: Identify the potential hazards present in your work environment, such as falling objects, sharp edges, electrical risks, or slippery surfaces. Choose work boots slip on that provide specific protection against these hazards, including steel toe caps, puncture-resistant soles, electrical hazard protection, or slip-resistant outsoles.

Tip 2: Prioritize Comfort and Fit: Work boots slip on should fit snugly without causing discomfort or excessive movement. Wear socks similar to those worn during work when trying on boots. Ensure adequate space in the toe box to prevent cramping. Discomfort can lead to fatigue and reduced productivity.

Tip 3: Choose Durable Materials: Look for work boots slip on made from high-quality materials like leather or rubber. Leather offers durability, flexibility, and protection, while rubber provides shock absorption and slip resistance. Avoid materials that are easily torn or punctured.

Tip 4: Consider Weather Conditions: If your work environment involves exposure to extreme temperatures, choose work boots slip on with insulation or waterproofing features. This will keep your feet comfortable and protected in all weather conditions.

Tip 5: Maintain Regularly: Clean your work boots slip on regularly with a damp cloth to remove dirt and debris. Leather boots may require occasional conditioning to preserve their durability. Avoid exposing the boots to extreme heat or chemicals, and allow them to dry thoroughly after use.

Tip 6: Inspect Frequently: Regularly inspect your work boots slip on for signs of wear or damage. Pay attention to the soles, uppers, and seams. Replace the boots if you notice significant wear or damage that compromises their protective capabilities.

Tip 7: Use Proper Footwear Inserts: If needed, use orthotic inserts or insoles to provide additional support and cushioning. This can help reduce fatigue and improve overall comfort.

Tip 8: Store Properly: When not in use, store your work boots slip on in a dry, well-ventilated area. Avoid storing them in direct sunlight or extreme temperatures, as this can damage the materials.

By following these tips, you can enhance the effectiveness, longevity, and comfort of your work boots slip on, ensuring optimal foot protection and support in your work environment.

Transition to the article’s conclusion: Understanding the importance and benefits of work boots slip on, as well as implementing these practical tips, can contribute to a safer and more productive work environment.

Conclusion

In conclusion, work boots slip on are an essential piece of personal protective equipment for individuals working in various industries. They provide crucial protection against workplace hazards, ensuring the safety and well-being of workers. Their comfort features minimize fatigue and discomfort, enhancing productivity and overall performance.

The versatility and durability of work boots slip on make them suitable for a wide range of work environments and specific job requirements. By selecting the right work boots slip on and following proper maintenance practices, individuals can maximize their effectiveness and longevity, contributing to a safer and more productive work environment.

Investing in high-quality work boots slip on is not only an investment in safety but also an investment in the health and well-being of the workforce. By prioritizing foot protection and comfort, organizations can foster a work environment where individuals can perform their duties with confidence and efficiency.